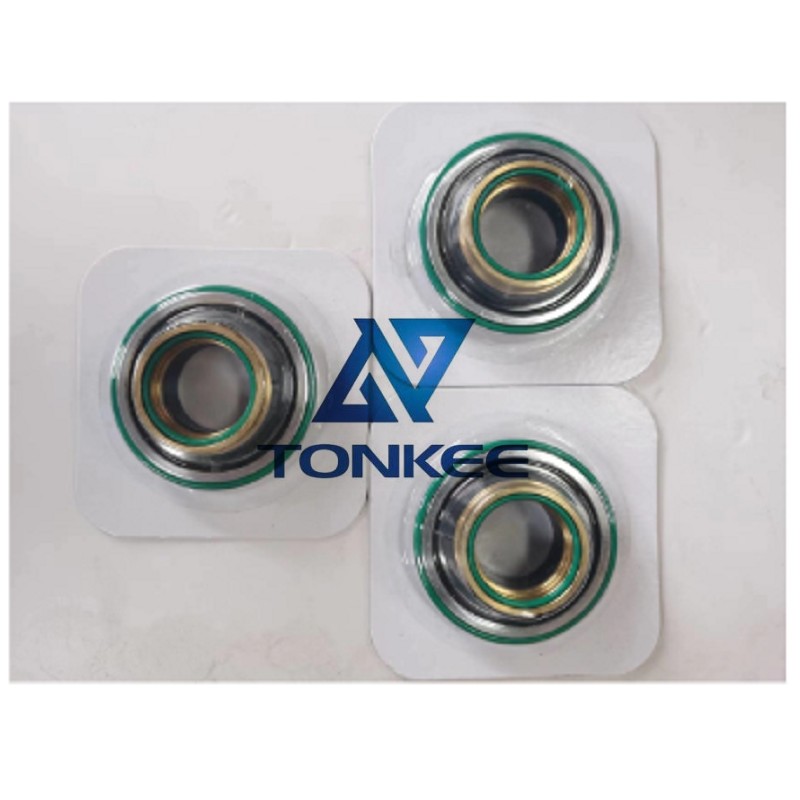

The mechanical seals used in the Sauer Danfoss SPV22, SPV23, SPV24, and SPV25 hydraulic pumps are designed to prevent fluid leakage and maintain the integrity of the hydraulic system.

They are critical for the efficiency and reliability of these pumps. These seals are typically made up of several components, including a stationary ring and a rotating ring, both of which are essential for maintaining a leak-free seal.

Materials:

The materials used in these mechanical seals are carefully chosen to withstand the harsh operating conditions of hydraulic systems. Common materials include high-grade carbon, ceramic, and various types of elastomers. Carbon and ceramic components provide excellent wear resistance and durability, while elastomers ensure proper sealing even under high pressures and varying temperatures.

Sealing Mechanism:

Mechanical seals operate on the principle of creating a barrier to prevent the escape of hydraulic fluid.

They work by maintaining a thin, dynamic film of oil between the rotating and stationary rings. This film of oil, or lubrication layer, acts as a barrier to prevent direct contact between the rings, reducing friction and wear. When the pump is in operation, the rotating ring rotates with the pump shaft, while the stationary ring remains in place. This relative motion creates a dynamic seal, effectively preventing fluid leakage.

Functions:

Leakage Prevention: The primary function of the mechanical seal is to prevent hydraulic fluid from escaping the pump. Leakage can lead to system inefficiency, contamination, and potential damage to components.

Friction Reduction: By maintaining a thin oil film, these seals minimize friction between the rotating and stationary rings, reducing wear and extending the service life of the seals and pump.

Temperature Control: Properly designed mechanical seals also help dissipate heat generated during pump operation, preventing overheating and ensuring the hydraulic system operates within its temperature limits.

Pressure Handling: Mechanical seals must withstand high pressures commonly found in hydraulic systems. The seal's design and material selection play a crucial role in ensuring it can handle these pressures effectively.

English

English Русский язык

Русский язык