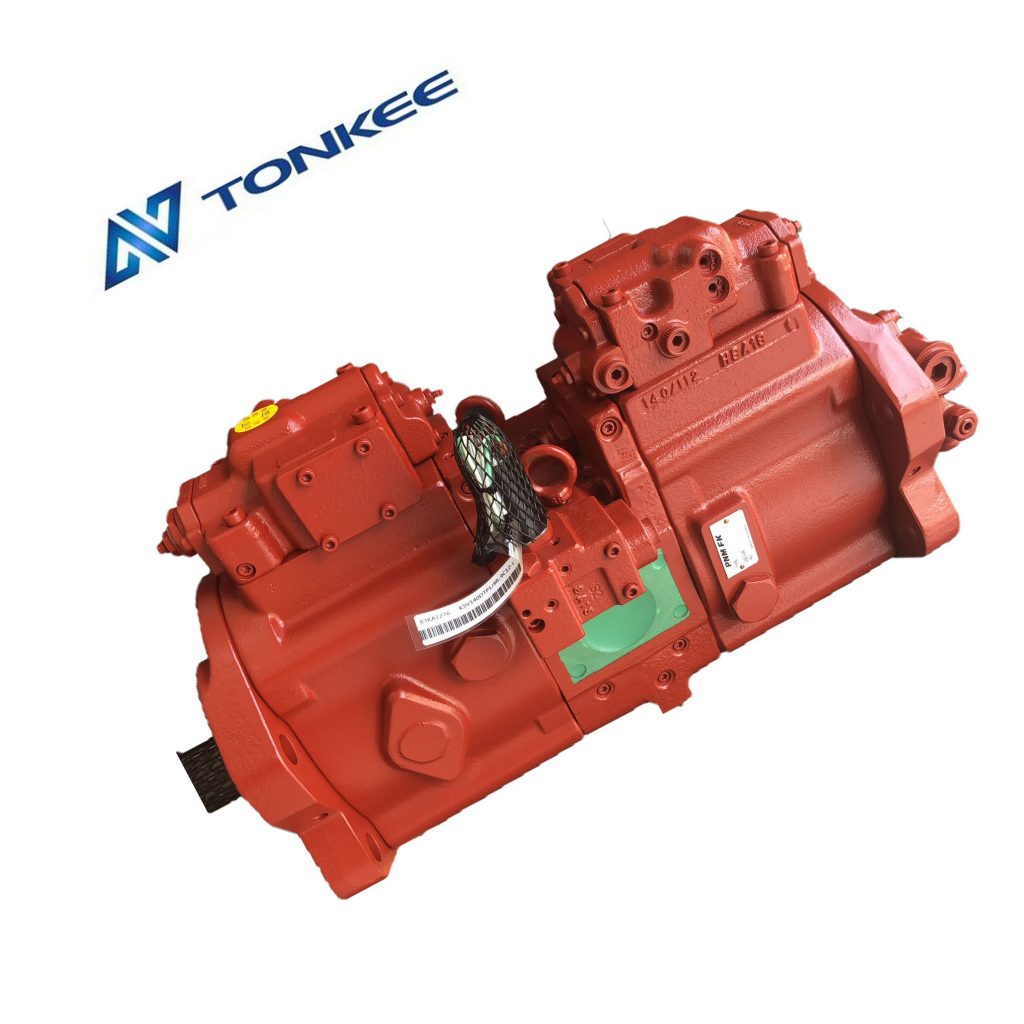

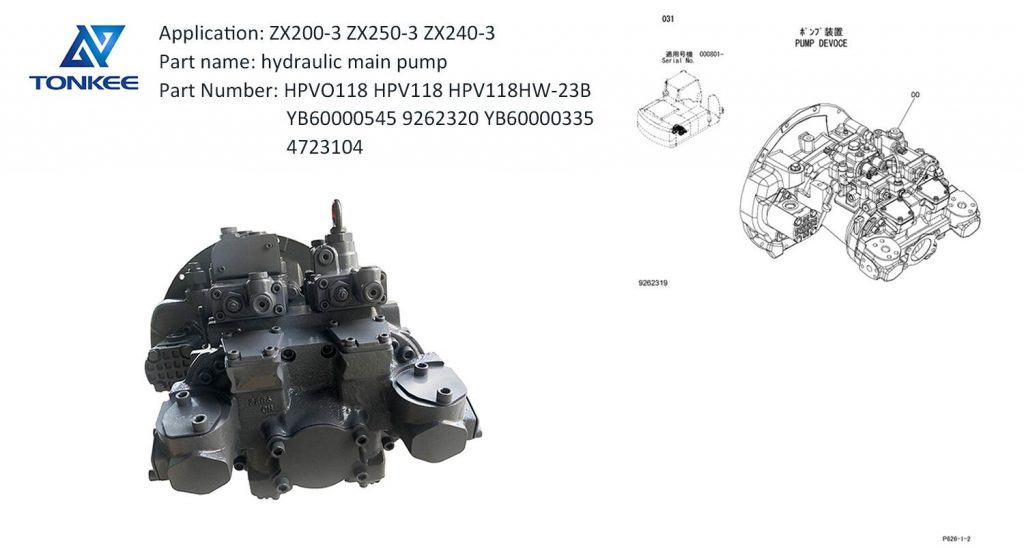

The pump's housing is typically made of high-strength materials, such as cast iron or aluminum, designed to withstand the pressures and forces involved in hydraulic systems.

The end caps securely enclose the housing, providing protection and support for the internal components.

Cylinder Block:

The heart of the PVB piston pump is the cylinder block. It contains multiple piston bores, each with a piston that moves in and out. The cylinder block is precision-machined to ensure a tight fit and minimize internal leakage. The bores are often designed with a swashplate mechanism for variable displacement control.

Pistons:

Pistons are the components responsible for generating hydraulic pressure. They are typically made from high-quality materials like hardened steel or ceramic and have seals to prevent fluid leakage. The size and number of pistons in the cylinder block vary depending on the pump's displacement.

Swashplate:

The swashplate is a critical part for variable displacement control in PVB series piston pumps. It can be tilted to adjust the piston stroke, which in turn controls the pump's output flow rate and pressure. The swashplate angle is set according to the hydraulic system's demand.

Port Plate:

The port plate connects the pump to the hydraulic system, providing inlet and outlet ports for the hydraulic fluid. It includes various passageways and controls to direct fluid flow within the pump and to the system.

Bearings:

Bearings are crucial for reducing friction and wear in the pump.

PVB series piston pumps commonly use high-quality, anti-friction bearings to support the swashplate and other moving parts within the pump.

Seals and Gaskets:

Seals and gaskets are essential for preventing fluid leakage and maintaining the pump's efficiency. These are often made from materials like nitrile rubber or polyurethane, designed to withstand hydraulic fluid and high pressures.

Control Mechanisms:

PVB series piston pumps can include various control mechanisms depending on the model. These may involve electronic controls, such as proportional solenoids, or manual controls for adjusting the swashplate angle and, consequently, the pump's output.

Pressure Relief Valves:

Pressure relief valves are often integrated into the pump to protect it and the hydraulic system from overpressure conditions. These valves open to divert excess fluid and maintain system pressure within safe limits.

English

English Русский язык

Русский язык