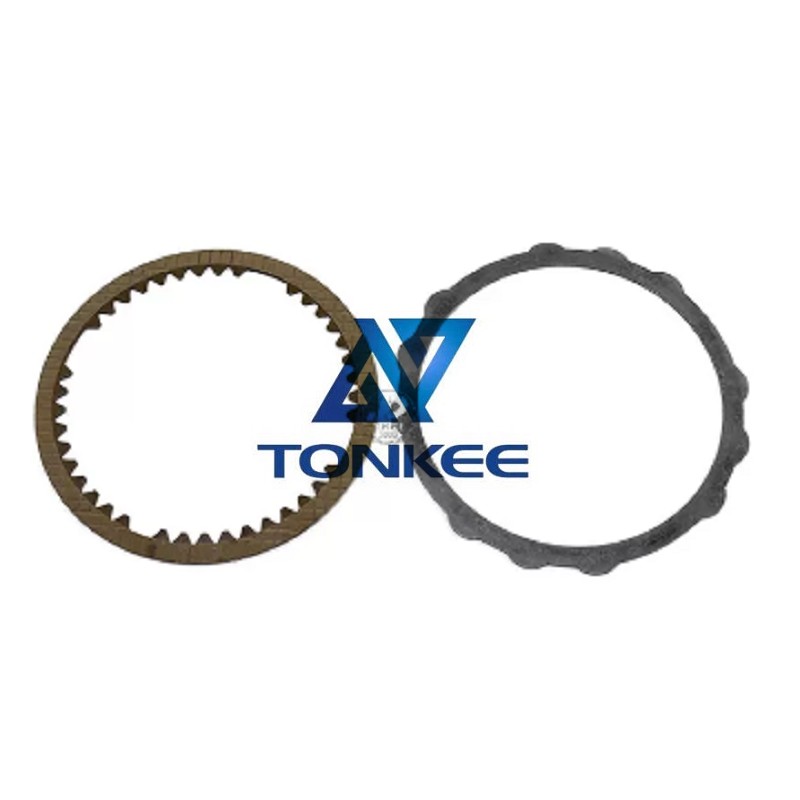

Material Composition: Separation friction plates are typically made from high-quality materials to ensure durability and reliable performance.

These materials are carefully selected to withstand the harsh conditions of hydraulic systems. Common materials used include steel, composite materials, and various friction materials.

Dimensions: The dimensions of separation friction plates can vary depending on the specific model and application. These plates are designed to fit precisely within the hydraulic pump or motor assembly. Accurate dimensions are crucial to ensure proper engagement and disengagement within the hydraulic system.

Friction Coefficient: The friction coefficient of separation friction plates is carefully engineered to provide the necessary friction for the smooth operation of hydraulic components. It is essential to strike a balance between high friction for efficient energy transfer and low friction for minimal wear and heat generation.

Heat Resistance: Hydraulic systems generate heat due to the constant movement of fluids and components. Separation friction plates must have excellent heat resistance properties to withstand elevated temperatures without losing their friction characteristics.

Wear Resistance: The separation friction plates are subjected to continuous contact and movement. They must exhibit excellent wear resistance to maintain their functionality over an extended period. This extends the service life of the hydraulic components.

Compatibility: Separation friction plates must be compatible with the specific hydraulic pump or motor they are designed for.

Different models and brands of hydraulic components may require unique separation friction plates to ensure a proper fit and function.

Importance of Separation Friction Plates in Kawasaki Motor Parts:

Separation friction plates play a critical role in the operation of hydraulic pumps and motors, such as the M2X146, M2X150, and M2X210 associated with Kawasaki Motors. Here's why they are essential:

Clutch Engagement: Separation friction plates are used in the clutch assembly of hydraulic components. They allow for the controlled engagement and disengagement of the hydraulic pump or motor, enabling precise control over fluid flow and system operation.

Energy Transfer: These plates facilitate the transfer of mechanical energy into hydraulic energy and vice versa. The controlled friction between the plates ensures efficient energy conversion, enabling the hydraulic system to perform work or power other machinery.

Longevity: High-quality separation friction plates contribute to the longevity of hydraulic components. They minimize wear and heat generation, extending the service life of the pump or motor and reducing maintenance costs.

Performance: The correct friction coefficient and material composition of these plates are essential for the optimal performance of the hydraulic system. Proper clutch engagement and disengagement directly impact system efficiency and responsiveness.

English

English Русский язык

Русский язык