The 704-11-38100 gear pump belongs to a family of positive displacement pumps.

It consists of two meshing gears – one is the driving gear (the rotor), and the other is the driven gear (the idler). These gears rotate in a sealed housing, creating chambers between the teeth as they move. As the gears mesh and unmesh, these chambers expand and contract, causing fluid to be drawn into the pump and then discharged.

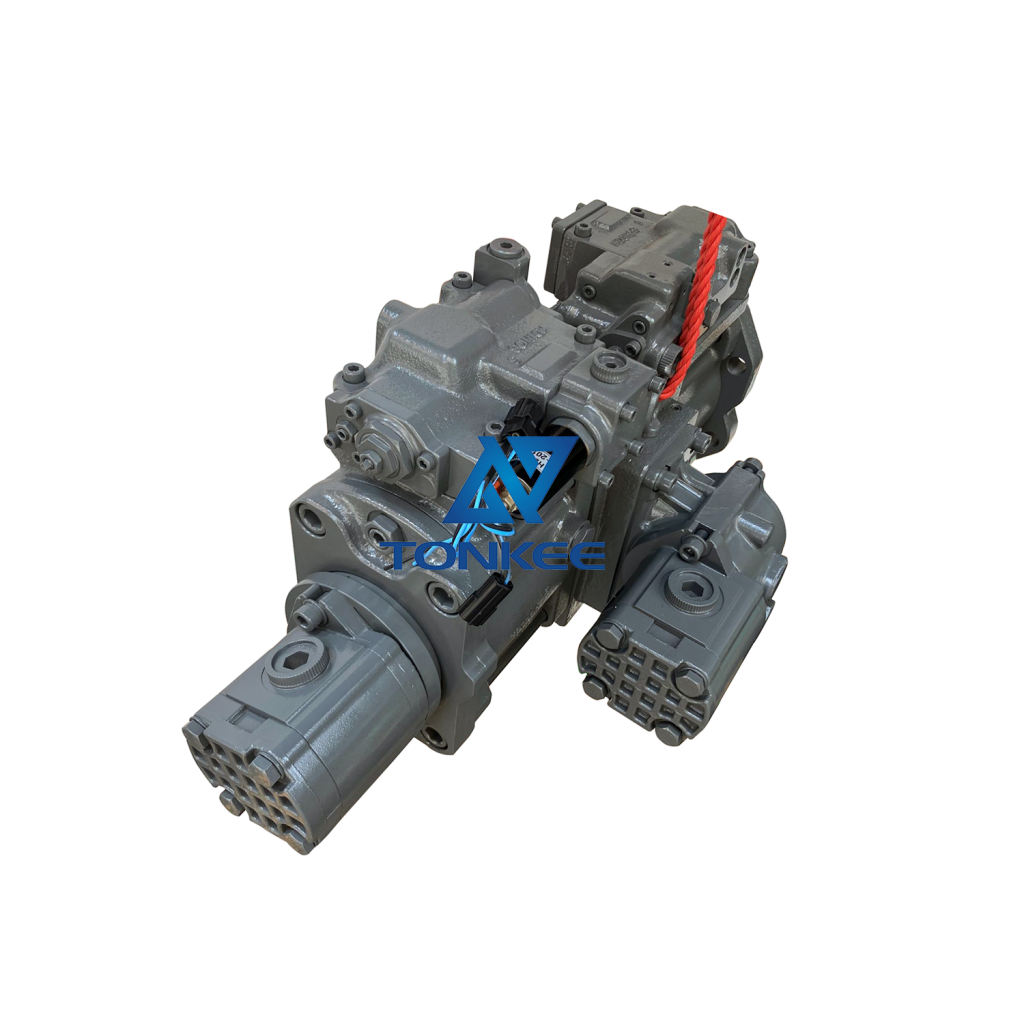

One of the most notable features of the 704-11-38100 gear pump is its compact and durable design. It is typically constructed from high-quality materials such as cast iron or aluminum, which ensures its longevity and resistance to wear and tear. The precision machining of its components guarantees minimal internal leakage, improving overall efficiency.

This gear pump is often chosen for applications that require a constant and smooth flow of hydraulic fluid. It offers a reliable solution for delivering hydraulic power in systems such as industrial machinery, construction equipment, and agricultural vehicles. Its ability to maintain consistent pressure and flow makes it ideal for powering various hydraulic functions, including actuating cylinders and controlling hydraulic motors.

The 704-11-38100 gear pump is known for its exceptional performance in terms of flow rates and pressure capabilities.

It can handle a wide range of fluid viscosities, making it versatile for different applications. The pump's design is optimized for low noise levels, ensuring a quiet and efficient operation. This is particularly important in applications where noise reduction is a priority.

This gear pump is driven by an external power source, typically an electric motor or an internal combustion engine. Its rotational speed directly affects the flow rate, and by controlling the speed, you can precisely adjust the hydraulic system's output. It is important to note that proper maintenance, including monitoring for wear and tear, is necessary to ensure the pump's longevity and reliable performance.

The 704-11-38100 gear pump is compatible with various types of hydraulic fluids, including mineral oil-based hydraulic fluids, synthetic oils, and biodegradable fluids. This flexibility allows it to adapt to the specific requirements of different applications, making it a versatile choice for hydraulic systems.

English

English Русский язык

Русский язык